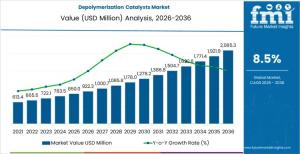

Depolymerization Catalysts Market 2026–2036: Chemical Recycling Expansion Drives 8.5% CAGR Growth

The depolymerization catalysts market is set to double by 2036 as chemical recycling scales, driven by efficiency, purity, and circular economy demand.

NEWARK, DE, UNITED STATES, January 19, 2026 /EINPresswire.com/ -- Global Market Overview: Growth Anchored in Chemical Recycling Scale-Up

The global Depolymerization Catalysts Market is poised for strong expansion as chemical recycling moves from pilot trials to commercial-scale infrastructure. The market is projected to grow from USD 922.3 million in 2026 to USD 2,085.3 million by 2036, advancing at a CAGR of 8.50%. While catalysts represent a small portion of total recycling plant capex, their influence on conversion efficiency, energy consumption, and monomer purity gives them a disproportionate impact on operating margins and long-term project viability.

Request For Sample Report | Customize Report | Purchase Full Report:

https://www.futuremarketinsights.com/reports/sample/rep-gb-31530

Value Creation: Why Catalysts Command Pricing Power

Value creation in the depolymerization catalysts market is driven less by sales volume and more by where catalysts sit within the chemical recycling cost structure. High-performance catalysts reduce deactivation rates, extend operating life, and stabilize output quality across variable waste streams. Early-stage recyclers often accept premium pricing to de-risk scale-up and ensure predictable performance. As facilities move toward commercial operation, cost pressure increases, yet switching barriers remain high due to deep process integration and qualification requirements. Between 2026 and 2036, value capture is expected to favor suppliers embedded in proprietary depolymerization platforms rather than commodity catalyst providers.

Key Market Drivers Supporting Long-Term Growth

The shift toward advanced chemical recycling infrastructure is the primary growth engine for depolymerization catalysts. Mechanical recycling struggles with contaminated, mixed, or multilayer plastic waste, creating strong demand for catalytic systems that break polymers back into reusable monomers or intermediates.

Key demand drivers include:

- Rising investment in chemical recycling to meet circular economy targets

- Regulatory mandates for recycled content and extended producer responsibility

- Growing downstream demand for virgin-equivalent recycled monomers

- Need to process complex plastic waste streams unsuitable for mechanical recycling

Catalysts enable controlled reactions such as glycolysis, methanolysis, hydrolysis, and hydrogenolysis, supporting higher recovery yields and improved product purity.

Performance Requirements Shaping Catalyst Adoption

End users increasingly evaluate depolymerization catalysts on technical performance rather than upfront cost. Catalyst efficiency, selectivity, and durability directly influence throughput and energy intensity. Both homogeneous and heterogeneous systems are being engineered to operate at lower temperatures and pressures, reducing operating costs.

Critical performance criteria include:

- High conversion rates and reaction selectivity

- Resistance to deactivation from additives and contaminants

- Compatibility with PET, polyamides, polyurethanes, and polyolefins

- Long catalyst lifetimes and regeneration capability

Suppliers that tailor catalysts to specific polymer chemistries gain competitive advantage by enabling stable, scalable operations.

Market Segmentation Insights: Feedstock and Catalyst Type

PET and polyester streams dominate the market, accounting for approximately 42% share, due to their chemical structure and large-scale availability in packaging and textiles. Established processing infrastructure and predictable reaction kinetics reduce operational risk.

From a technology perspective, metal-based catalysts hold around 38% share, favored for their high activity, thermal stability, and compatibility with continuous industrial processes. Their robustness and reusability make them the preferred option for large-scale depolymerization facilities.

Regional Growth Outlook: Where Demand Is Accelerating

Growth patterns vary by region, shaped by waste generation volumes, recycling investment, and industrial integration.

- China: Leading growth at 9.7% CAGR, driven by large polymer production and rapid commercialization of chemical recycling

- Brazil: Emerging market with 9.3% CAGR, supported by rising post-consumer waste and early-stage chemical recycling projects

- United States: Growing at 8.2% CAGR, fueled by strong investment in commercial depolymerization plants

- Germany: 8.1% CAGR, focused on efficiency optimization and precision engineering

- South Korea: 7.7% CAGR, driven by integration with petrochemical manufacturing

Competitive Landscape: Performance Over Price

Competition in the depolymerization catalysts market is defined by catalytic efficiency, selectivity, and integration with commercial recycling processes. Leading players such as Clariant AG, BASF SE, Johnson Matthey, Evonik Industries AG, and Mitsubishi Chemical Group leverage advanced catalysis expertise to differentiate their offerings. Strategic collaborations involving SK Geo Centric, Indorama Ventures, Eastman Chemical Company, Loop Industries, and Ineos Styrolution are blurring traditional supplier boundaries by combining catalyst technology with full depolymerization systems. Across the market, success is increasingly tied to performance reliability rather than material cost alone.

Market Outlook: Strategic Importance Continues to Rise

As chemical recycling capacity expands globally, depolymerization catalysts will play a foundational role in enabling scalable, economically viable circular material flows. Suppliers that combine catalyst performance with process integration and technical collaboration are best positioned to capture long-term value.

Related Reports:

Terephthalic Aldehyde Market- https://www.futuremarketinsights.com/reports/terephthalic-aldehyde-market

Electroplating Market- https://www.futuremarketinsights.com/reports/electroplating-market

Biomass Pellets Market- https://www.futuremarketinsights.com/reports/biomass-pellets-market

Have a specific Requirements and Need Assistant on Report Pricing or Limited Budget please contact us - sales@futuremarketinsights.com

About Future Market Insights (FMI)

Future Market Insights, Inc. (FMI) is an ESOMAR-certified, ISO 9001:2015 market research and consulting organization, trusted by Fortune 500 clients and global enterprises. With operations in the U.S., UK, India, and Dubai, FMI provides data-backed insights and strategic intelligence across 30+ industries and 1200 markets worldwide.

Contact Us:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-347-918-3531

Why FMI: https://www.futuremarketinsights.com/why-fmi

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

LinkedIn| Twitter| Blogs | YouTube

Sudip Saha

Future Market Insights Inc.

+1 347-918-3531

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.